1. Introduction

Do you know angle grinders have become a fundamental tool in metalworking, fabrication, and construction industries? With this tool, it is far more convenient to tackle some of the most difficult and laborious tasks such as grinding, cutting, and polishing.

Similarly, we are seeing innovation in the angle grinders market. For instance, new models are coming with amazing features such as performance tracking, maintenance reminders, and data analysis. This latest development will enable us to analyze these tools' performance in the future.

But which is the best option in angle grinders; corded or cordless?

In this guide, we shall go through the definition of angle grinders, their applications, and some of the best features of this tool. Ultimately, you will be able to choose between corded and cordless angle grinders following your project requirements.

So, let’s start with the definition and move forward step by step.

2 What is an angle grinder?

An angle grinder is one of many power tools that allow you to process various surfaces and prepare them for subsequent work or give them a final finish. This device has the ability to replace discs, so it can be used for metal, ceramics or concrete, depending on the selected equipment. With this tool, you can quickly get rid of unwanted parts and cut the material to a specific size and shape.

2.1 What Consider When Selecting an Angle Grinder

When choosing an angle grinder, you need to focus on its application purpose, and understand under what conditions the tool will be used and with what materials. The scope of application of the grinder is large: cutting, grinding, and polishing work.

2.1.1 Home and professional use

For use at home, a small angle grinder with a circle diameter of 115–150 mm is suitable. Such grinders are used when installing a fence in a suburban area, sawing pipes when replacing them, and assembling metal structures. When cutting metal, the tool must have a power of at least 850 W, and for brick - 1200 W.

Large professional grinders use discs with a diameter of 180–230 mm. Angles with a power of 2000 W are designed for grinding work, 2200 W for cutting metal, and more than 2400 W for masonry. Professional grinders have improved dust protection - a double varnish coating.

2.1 .2 Diameter of Nozzles and Discs

The performance of the grinder is determined largely by the maximum diameter of the discs used. The larger the diameter, the deeper the cut can be made. Angle grinders are available in five standard sizes. Almost all discs have a standard seat size of 22.2 mm.

2.1 .3 RPM Speed

The larger the diameter of the nozzles used, the lower the rotation speed required. Professional grinders, which allow you to work with discs with a diameter of up to 230 millimeters, are almost always equipped with speed control.

The characteristics always indicate the maximum idle speed of the disk. During operation, the speed of rotation almost always decreases due to the resistance of the materials. Grinders with constant electronics allow you to maintain a given speed regardless of what material you have to work with.

The operating speed range is approximately from 2800 to 11000 rpm. The permissible rotation speed of the disk is always indicated in the instructions for the tool, and often on a special plate on the body.

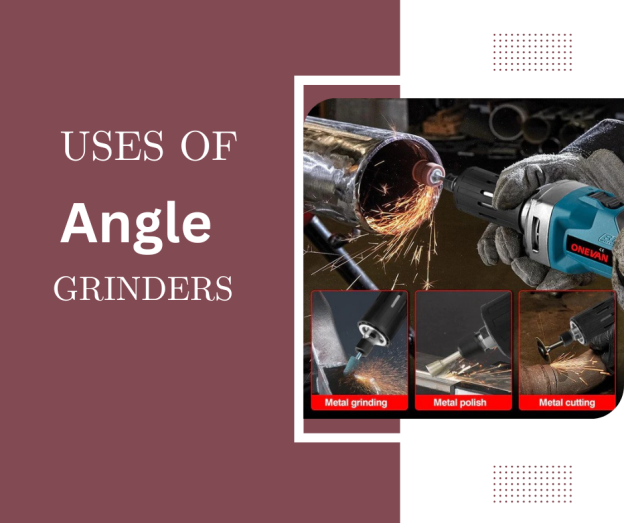

3.The Uses of Angle Grinders

The power of an angle grinder lies in its versatile features. It can tackle some of the most challenging tasks such as chopping tough materials and excellent surface finish. You just need to put the right attachment following your project requirements.

3.1 Cutting:

Metal:

Metal is one of the most popular choices for angle grinders. Equipped with an abrasive cut-off wheel, it can conveniently chop off steel, pipes, rods, and even sheet metal.

Tiles:

Do you need a highly precise cut in ceramic or stone tiles? Angle grinders with diamond cut-off wheels provide controlled cuts which enables precision cutting.

Concrete:

An angle cutter with diamond blades is perfectly used for quick cuts in slabs and pavers.

3.2 Grinding and Sharpening:

Tool Maintenance:

A grinding wheel on an angle grinder can maintain blunt lawnmower blades, dull chisels, or even rusty axes. This tool significantly restores sharpness and extends the tooling life.

Surface Prep:

Grinding discs on angle grinders remove rust, paint, or weld slag. These tools are highly effective at cleaning and prepping surfaces for further work.

Sharpening Expertise:

Angle grinders with special wheels can be used for sharpening several tools such as:

3.3 Sanding and Polishing:

Woodworking Finesse:

Generally, angle grinders are used for heavy-duty materials. However, in woodworking, you need a delicate touch. Sanding discs have various grits. By changing the grinding wheel with a sanding disc, you transform the angle grinder into a powerful sander

Metallic Shine:

Polishing discs or wire wheel attachments can be used with angle grinders to bluff the metal surface and remove heavy surface imperfections such as rust and oxidation.

3.4 Specialty Applications:

Since angle grinders have diverse features we can use them for multiple purposes with specific attachments.

4.Corded vs. Cordless Angle Grinders

4.1 Market Share and Trends of Corded and Cordless Angle Grinders

According to the latest research, the angle grinder market is experiencing steady growth, fueled by rising demand in construction, metal fabrication, and DIY projects. We have tried to provide valuable insights into consumer preferences and purchasing patterns.

4.1.1 Market Size and Growth:

The angle grinder market has shown significant growth, with a value of USD 3.17 billion in 2021 and a projected increase to USD 4.34 billion by 2030.

Similarly, another research held by The Business Research Company, with a projected increase from $3.14 billion in 2023 to $3.25 billion in 2024, the market is set to grow at a compound annual growth rate (CAGR) of 3.7%.

4.1.2 Corded vs. Cordless Market Share:

According to the Global Outlook & Forecast 2023-2028 report on the cordless power tools market which is expected to reach USD 37.87 billion by 2028, showing a substantial increase from USD 24.50 billion in 2022.

4.1.3 Forecasts and Trends:

In the cordless angle grinder, we can see a significant growth in battery technology like Lithium-ion (Li-ion). Making them a tough competitor in terms of power and performance compared to the corded grinders.

Simultaneously, corded grinders will remain a favorite choice due to their unparalleled power support and lower prices.

4.2 Difference Between Corded and Cordless Angle Grinders

Everyone is familiar with the angle grinder - a tool without which repairs and construction projects are indispensable. Thanks to a wide selection of accessories, an angle grinder can cut and grind metal, brick, granite, concrete, and ceramic tiles, carry out cleaning work, and even saw wood.

Cordless angle grinders have gained popularity because their performance has now become higher and today they can easily compete with corded tools. This became possible due to the use of batteries with high voltage and capacity, and thanks to the introduction of modern technological solutions such as a brushless motor.

| Feature | Corded Angle Grinder | Cordless Angle Grinder |

|

Power Output |

Higher and more consistent power output |

Lower power output compared to corded models. |

| Runtime |

Unlimited runtime as long as plugged into a power source. |

Limited runtime is usually based on battery capacity. |

| Mobility |

Limited mobility due to the length of the power cord. |

Highly portable and maneuverable. |

|

Convenience |

Always ready to use. |

Requires spare batteries charged or readily available. |

|

Maintenance |

Generally required lower maintenance |

Battery maintenance and replacement over time. |

4.3 The feedback of Corded and Cordless Angle Grinders

The debates between corded and cordless angle grinders have been a hot cake always. Both hobbyists and professionals have different opinions.

“Corded grinders deliver unmatched power and performance for tough jobs such as cutting thick steel beams.” Mark- A Welder

“Cordless angle grinders are a great option for those who prioritize safety and freedom. These grinders allow easy navigation in tight spaces.” Sarah, a carpenter

“Cordless grinders are the best choice for small projects. They are easier to move and significantly impact project performance compared to bulkier corded grinders.” Jane, a DIY Enthusiast

5. How to Use of Angle Grinders: A Step-by-Step Guide

5.1 Getting Started: Preparing Your Angle Grinder for Use

An angle grinder is an indispensable tool, but it is also the most dangerous. That is why it is necessary to know and follow the rules for safe working with it.

Without following the rules, this tool becomes extremely dangerous, so it is better not to work with it while drunk, very tired, or without sleep.

Before starting work, it is recommended to prepare all the necessary protective equipment. It is imperative to have special glasses and a casing on hand. Sparks can hit the face, especially the eyes, causing injury.

Before working with the unit, it is necessary to prepare the following accessories:

An angle grinder is powered by an electric motor, which is powered by a 220V or a built-in battery.

The design and the details of angle grinders are almost the same, regardless of the type. Different models vary in functional features, depending on the type of work being executed.

Inside the housing there is an electric motor consisting of:

The engine is started using a button located on the body. By smoothly starting the tool into operation, the speed of rotation is gradually increased, preventing overload of the motor.

5.2 Step-by-Step: How to Safely and Effectively Use Angle Grinders

5.3 Tips and Tricks: Enhancing Your Technique and Efficiency with Angle Grinders

If you are going to cut a concrete wall with a grinder, using a special diamond disc with a diameter of 230 mm for this purpose, remember that the maximum permissible cutting depth for it is 60-65 mm, and it is not recommended to go deeper than 20-25 in one pass mm.

Very often, angle grinder users violate angle grinder safety requirements by trying to install a larger diameter disk for lack of the required one, for which they remove the protective casing. This is very dangerous for both the tool and the person using it! An attempt to install a saw blade into an angle grinder can also lead to very unpleasant consequences. Please remember that such actions can result in serious injury!

6.Angle Grinder Safety and Maintenance Tips

Knowing the rules for working with an angle grinder and cutting discs reduces the risk of injury and increases the quality of the work performed. The main conditions for safe operation are a working tool and power supply, the use of personal protective equipment (gloves, goggles, work clothes), and the correct selection of equipment.

List of required PPE:

6.1 Maintenance Tips for Angle Grinders

The first step is to take care of protecting the angle grinder motor from dust and overload. Metal and abrasive dust can cause serious damage to the tool - the first can cause an electrical short, and the second poses a danger to bearings and mechanical transmissions. Modern angle grinders are often equipped with a dust removal system that helps solve this problem, but you shouldn’t rely on it alone.

Low temperatures also adversely affect the condition of angle grinders. For this reason, it is not recommended to leave the tool in cold rooms over the winter.

6.2 Common Troubleshooting Issues and How to resolve them?

Angle grinders are extremely powerful and reliable tools but they can also face occasional hiccups. We have mentioned some below and also shared how to fix the issues.

1: Problem: The grinder won't turn on.

Solution: Check the power source.

2: Problem: The grinder lacks power

Solution: Use the correct disc or wheel. Also check out the worn bushes

3:Problem: Excessive vibration

Solution: Tighten the disc or wheel

7.Conclusion

Whether you're a seasoned professional or a DIY enthusiast, choosing the right angle grinder significantly depends on particular project and material requirements. Where corded angle grinders provide power, and lower upfront costs, cordless angle grinders offer superior maneuverability and reduce potential tripping hazards.

At OneVan, you can find 3 types of brushless electric angle grinders for a range of purposes:

All grinders are capable of grinding, cutting, sanding, and polishing anything from metal to masonry. Ranging from 12v to 18v all angle grinders come with the freedom of cordless operations. Shop today to save up to 15% discount.

8. FAQs

1.What exactly is an angle grinder?Angle grinders are highly versatile tools that can be used by both DIY enthusiasts and professionals. They are valuable for a wide range of projects, from simple home repair tasks to more complex industrial applications.

2. Can angle grinders be used by DIY enthusiasts, or are they only for professionals?

Angle grinders are highly versatile tools that can be used by both DIY enthusiasts and professionals. They are valuable for a wide range of projects, from simple home repair tasks to more complex industrial applications.

3. What are the key factors to consider when choosing between a corded and cordless angle grinder?

The key factors include power needs (corded grinders typically offer more consistent power), mobility and convenience (cordless grinders provide greater freedom of movement), runtime, and the types of projects you plan to undertake.

4. Are there any safety concerns I should be aware of when using an angle grinder?

Yes, using an angle grinder comes with several safety concerns, such as the risk of kickback, flying debris, and potential cuts or burns. It's essential to wear appropriate safety gear, including gloves, goggles, and ear protection, and to follow the manufacturer's safety guidelines.

5. What are some common uses for angle grinders?

Common uses include cutting metal bars, pipes, tiles, and concrete; grinding and sharpening tools and blades; sanding and polishing metal and wood surfaces; and removing rust and paint.

6. How do I maintain my angle grinder?

Routine maintenance includes checking and replacing worn discs, ensuring all parts are tight and secure, regularly cleaning the tool to prevent dust buildup, and storing it properly when not in use. Always refer to your tool's manual for specific maintenance recommendations.

7. Can angle grinders cut through all types of materials?

Angle grinders can cut through a variety of materials, but the capability depends on the type of disc used. Different discs are designed for metal, concrete, tile, and wood. Always use the appropriate disc for the material you are working with.

8. How do I choose the right disc size for my angle grinder?

The right disc size depends on the nature of your project and the depth of cut required. Larger discs can cut deeper but may be more challenging to handle. Consider the specifications of your angle grinder and the requirements of your project when selecting a disc size.

9. What's the difference between grinding and cutting discs?

Grinding discs are thicker and used for heavier grinding work, such as smoothing out welds or removing material. Cutting discs are thinner and designed for making precise cuts in various materials. Using the correct disc is crucial for the task at hand and safety.

10. Can I use attachments other than discs with my angle grinder?

Yes, angle grinders can be fitted with various attachments besides discs, such as wire brushes for cleaning rust and paint, flap discs for sanding, and diamond blades for cutting hard materials. Ensure any attachment is compatible with your angle grinder model.